Routing the basics of Wire Harnesses

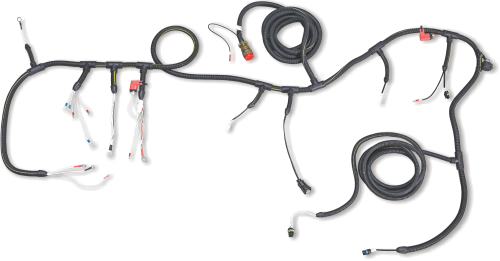

Wire harnessing is an assembly process involving the assembly of conduits, wires, connectors, terminals into one structured cord. A wiring harness enables transmission of signals, electric power and relaying information within the connected electrical or electronic system. Inevitably, playing a crucial role of connecting various components of any system.

What Is Wiring Harness?

Regardless of the application, a wiring harness will have three basic components: Wires, Connectors & Terminals. A safe, cost-effective and efficient approach to connect a system, a wire harness assembly maximizes efficiency by routing several wires together with connectors & terminals at either ends of the wire, specific to the application. This assembly is structured as a single component by employing one or several wire management products like conduits, tubing, cable ties and other sleeving types.

The outermost cover of any wiring harness can be either in the form of slit or unslit conduits or braiding, tubing. This component of the harness not only keeps the multiple wires organized but also protects the wire assembly from extreme on-site temperatures, general wear & tear, friction and several other persisting environmental conditions.

Why Is It Efficient?

Why all industries, be it mechanical, electrical, or any other, go for wiring harnesses is because it makes electrical connections less complicated. It provides a structure to wiring that makes it easier to troubleshoot, if any error to were occur in the connected system.

Wires to electrical connections are what veins to the human body. It is necessary to make them well-ordered and risk-free for the smooth performance of the entire plant.

Using wiring harnesses secures and makes it safe for the human force working in the plant. It lowers down the chances of massive loss due to malfunctioning or short circuits.

A Guide to Design Wiring Harness

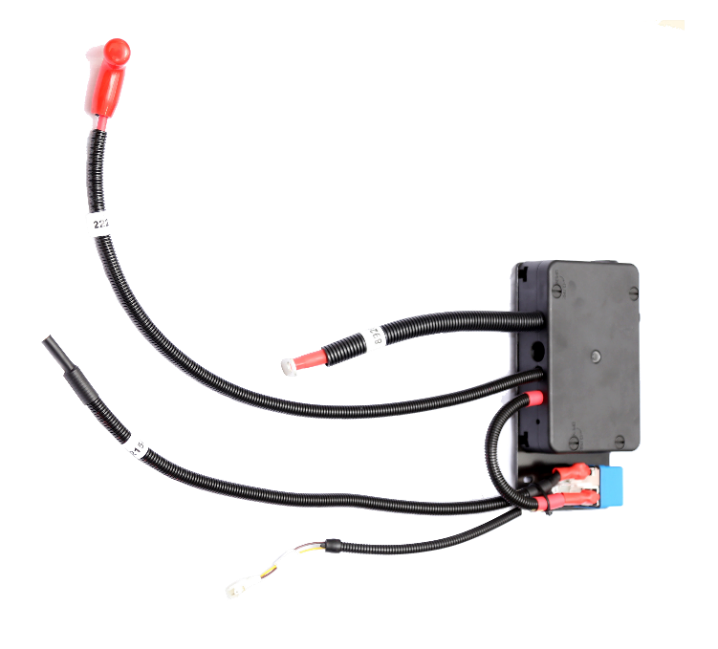

Wiring harness is designed according to the electrical and geometric requirements of the industry and the application. Followed by understanding of the application selection of connectors, terminals and other components followed by finalizing electrical/wiring diagrams further processes like wire cutting, stripping, terminal crimping, wire laying leading to assembly of all components in a single wire harness takes place.

As mentioned earlier, wires, connectors & terminals form the fundamental parts of the wire harness; where the latter two parts essentially form the backbone of any wire harness. The selection of terminals and connectors largely determine the overall stability, performance and reliability of the harness.

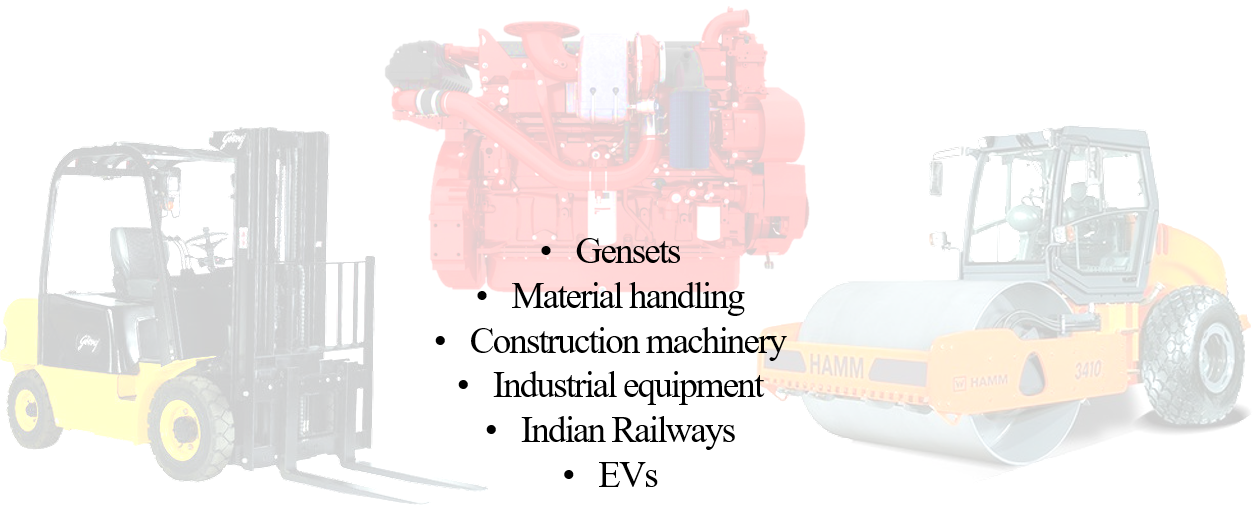

UNI-TECH Automation has been proving their exemplar capabilities in wire harness manufacturing and offering related technical solutions for the past 24 years. Off-highway, Material handling, Agriculture equipment, Genset manufacturers, etc. are a few industries UNI-TECH caters to, when it comes to manufacturing finest, defect-free wiring harness.

Need more detailed information?

Get a detailed wiring harness information from one of the profound wiring harness manufacturers in India. Visit or call UNI-TECH Automation for further details.

+918390039700 / https://www.uni-techautomation.com/